Download Brochure

brochure.pdfSwing Check Valves

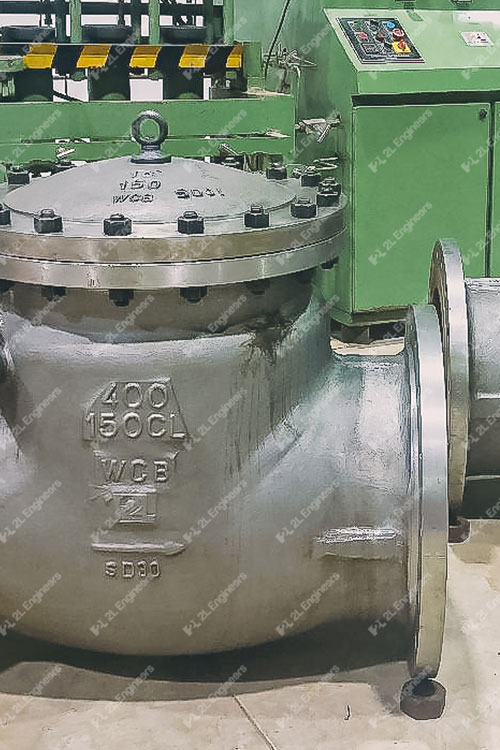

2L Engineers is the leading Swing Check Valve Manufacturer in INDIA

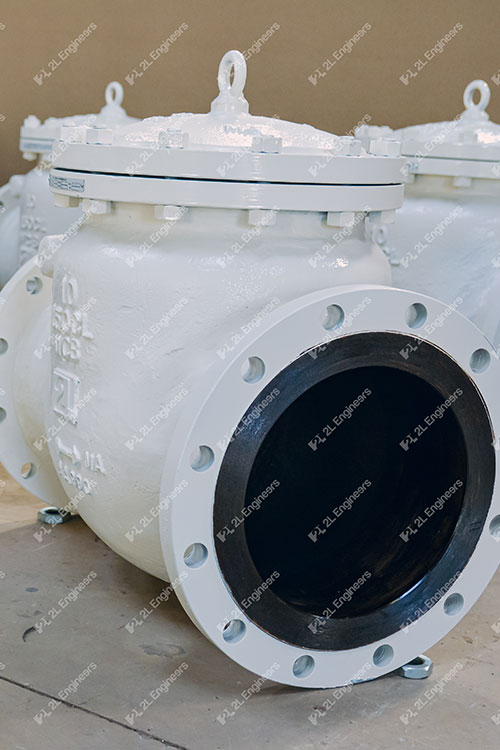

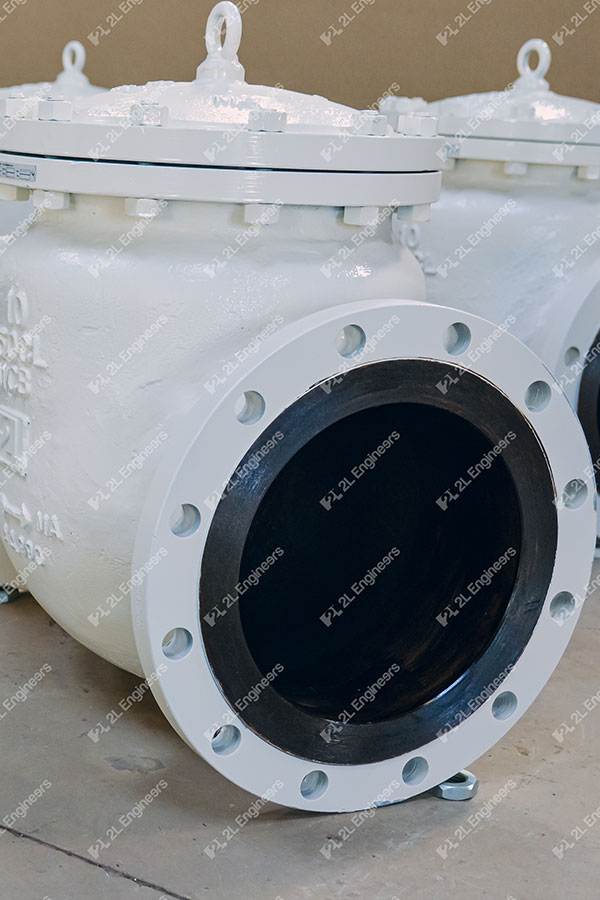

Swing check valve is a type of check valve that uses a swinging disc to allow or block fluid flow. It is designed to prevent backflow and ensure unidirectional flow in a pipeline. The disc swings open to allow flow in one direction and swings closed to block reverse flow, ensuring system integrity and efficiency. Swing check valves are commonly used in various applications, including water, oil, and gas industries, and are available in different materials to suit specific requirements. For different types and configurations of materials of construction, contact 2L Engineers for a detailed General Assembly Drawing (GAD).

2L Engineers also specialises in manufacturing of Cryogenic Check Valves for low temperature applications.

Technical Details

Special Features

|

Design Standards

Face to Face

Testing Standard

|

End Connections

|

Sizes Range

|

Pressure rating

|

Operations

|

Shutoff Rating

|

|

| Material Type Specification: | ||

|---|---|---|

| Type of Service: | Valve Shell Material: | Pressure Controlling Parts & Stem: |

| General Service | Carbon or Low-Alloy Steel | Carbon or Low-Alloy Steel |

| General Service | Carbon or Low-Alloy Steel | Stainless Steel |

| General Service | Stainless Steel | Stainless Steel |

| Sour Service | Carbon or Low-Alloy Steel | Carbon or Low-Alloy Steel |

| Sour Service | Carbon or Low-Alloy Steel | Stainless Steel |

| Sour Service | Stainless Steel | Stainless Steel |

| Sour Service | CRA ( Corrosion Resistant Alloy) | CRA ( Corrosion Resistant Alloy) |